You are here

Strand Welding

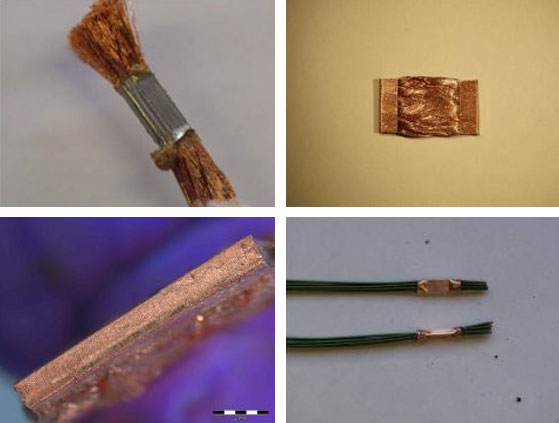

Stranded wire welding is ideally suited for stranded tinned wires. It applies an even, intense and massive compression. When compared to ultrasonic compacting, the surface of a resistance welding wire is even and not curled.

Typical applications are sensors in the electronics industry, Y connectors in the solar and automotive industries and enamelled wires for motor and high frequency.

AMADA WELD TECH has acquired extensive knowledge in strand welding and can offer a wide range of applications. We can provide solutions for your specific applications to join cables with large dimensions, mostly found in the automotive industry.

This two-step process consists of compacting and brazing. One proven application is a so-called intelligent battery sensor which allows battery power management. The result is a robust and very strong joint that has a perfect electrical connection over the lifetime of the product. The cable is contacted directly to the sensor tab without any additional parts.

Typical Strand Welding Applications

Benefits of Strand Welding:

- Evenly compacted compression, no individual strands in compacted area

- Wire surface remains even and does not curl

- Perfectly and repeatedly meets the specific welding requirements for sensors, Y connectors and enameled wires