You are here

Weld Monitoring

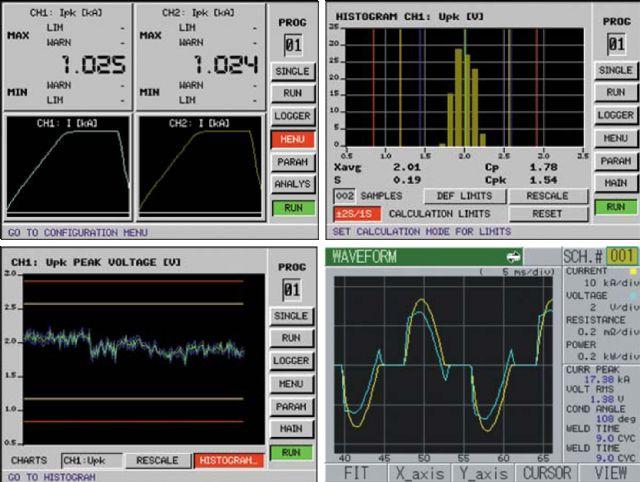

With an increased emphasis on the accountability and traceability of resistance welding processes comes the need for process monitoring and enhanced process control. To compliment the range of resistance welding equipment, AMADA WELD TECH offer a range of Weld Monitors to suit most applications and close the quality loop on your process.

Weld Monitoring offers the tools required for process development, production monitoring, data collection and analysis to support your quality system requirements.

Our four parameters for monitoring:

- Welding current

- Welding voltage

- Electrode penetration

- Electrode force

For many relatively simple processes such as welding ferrous metals, controlling the absolute current and voltage limit values suffices. However, increased monitoring is required for critical bonds, such as certain copper alloy bonds. In this case too, the above four parameters can be monitored for instance not only within fixed limits, but also within envelope waveforms.

Weld Monitoring Benefits

AMADA WELD TECH offers a variety of weld monitoring devices with different benefits. Some of the devices are compact handheld units which remove the user’s dependency from power and PC hardware. Others are reliable and robust units which enable the convenient storage and transfer of data. The high-end versions are equipped with a one-button toggle wheel handling concept and have sophisticated and intuitive multilingual software. For more details, please consult the related products section below.

Weld Monitoring Products

AMADA WELD TECH offers a variety of different weld monitoring devices. The measurement devices meet customers’ requirements for easy-to-use, economical monitoring equipment that can be smoothly integrated into the production process. The new MM-400A is equipped with a USB port for convenient data transfer. Our new MM-410A meets the needs of users who are looking for a mobile system to reliably measure critical weld parameters. In practice, the affordable MM-122A measurement device already enables most welding processes to be reliably monitored.

The high-end version, MG3 Digital, offers an ultra-modern, high-performance and economical measurement device. It covers all application scenarios in micro-resistance welding from process development tool to monitoring device in the production line.

Applications of Weld Monitoring

AMADA WELD TECH Weld Monitors are state-of-the-art tools for resistance weld monitoring. They provide precise, real-time and dynamic measurement of all welding variables and are invaluable for:

- Process Development: Welding Evaluation and Research, DoE Studies, Process Optimization, Process Validation

- Process Monitoring: Data Logging, Setting Process Limits, Electrode Maintenance, Troubleshooting, Set-up Verification, Statistical Process Control

- Quality Control: Traceability, Process Certification and Analysis, Calibration Confirmation, Statistical Process Control