You are here

Batteries

Batteries come in many differing shapes and sizes, ranging from miniature cells used to power hearing aids and watches, to battery banks that provide standby power for telephone exchanges and computer data centres.

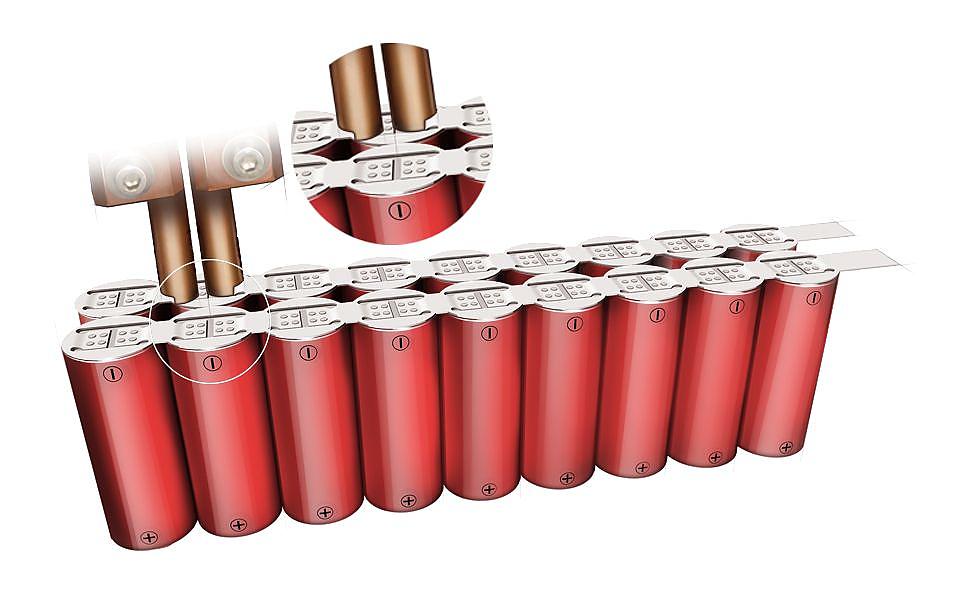

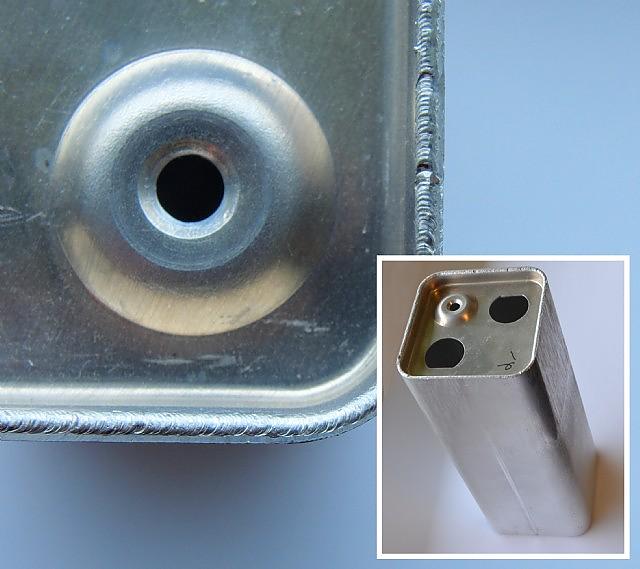

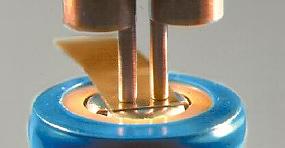

There are many joining requirements in battery manufacturing, including both internal and external connections and can or fill-plug sealing. Laser welding is often used to join the internal electrode materials that make up the internals of the cell. These are typically constructed from thin copper and aluminium foils. The remaining joints, including the connections inside the can and the external terminal tab connections, are suited to both resistance and laser welding. The decision to use one technology over another is determined both by the type of weld required and production requirements, such as high volume and material compatibility.

AMADA WELD TECH has a vast amount of experience with welding and marking batteries, including lithium ion, nickel-metal hydride, lead acid, nickel-cadmium and alkaline batteries in many different sizes: N - all sizes, AAA (LR03 / R03) - all sizes, AA (LR6 / R6) - all sizes, Sub C & C, D. Our expertise and combined technologies are used on many applications throughout the battery manufacturing industry. The technologies used for battery-pack welding include laser marking of cell cans, laser welding of cans, projection welding of battery caps, resistance welding of battery tabs to coin cells and laser welding of battery tabs to produce battery packs. The end product are widely used for applications such as power tools, medical instruments, mobile devices, electric power trains in hybrid and electric vehicles, wind turbines and much more.