You are here

Thermocompression Welding

AMADA WELD TECH offers a variety of resistance welding methods. Thermo-compression welding - also called “thermo-compression bonding” - is used to produce joints through the principle of “indirect heating”. The two parts are joined under the simultaneous influence of force and heat. The type of bond corresponds to diffusion welding, i.e. the bond is not produced by melting at the contact points, but by metallic solid-body diffusion.

One of the most common materials used is gold. Gold is especially preferred due to its excellent resistance to oxidation. Other materials can be bonded as well but the oxidation needs to be removed before bonding.

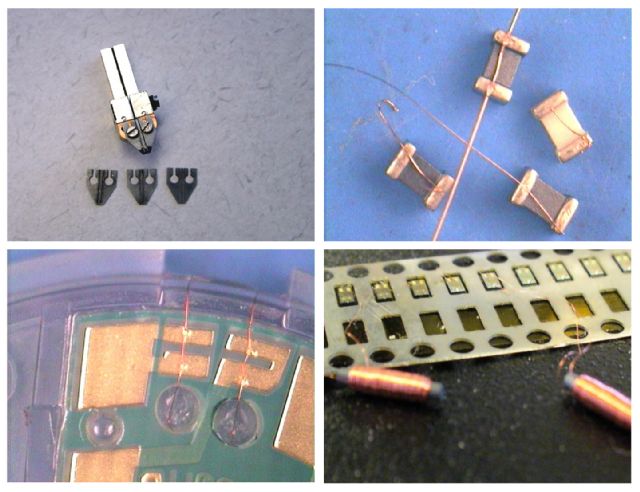

Thermo-compression Welding Applications

Benefits of Thermocompression Welding:

- Offers excellent connections when soldering and welding are not possible

- Low heat input

- Absence of melting

- Relatively short heating times

- Little or no deformation of the parts being joined

- Excellent shear and tensile strength